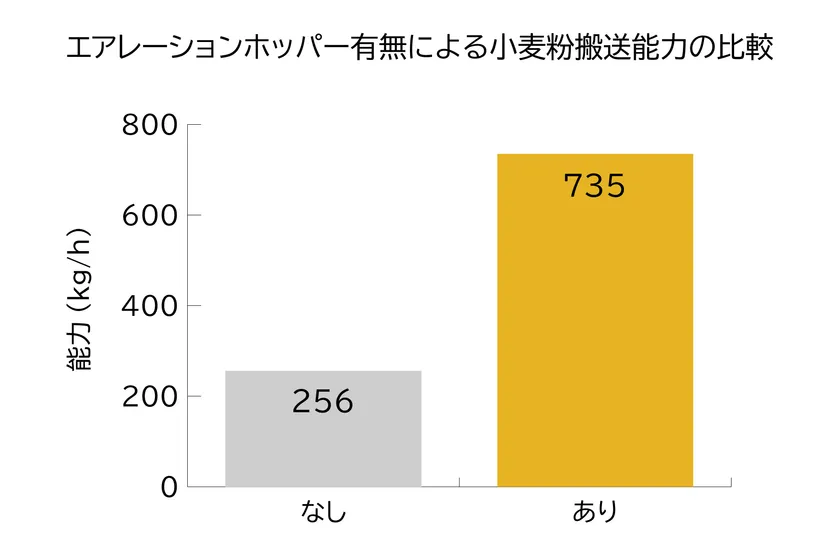

Flour conveying efficiency increased 2.87 times Experimental data showing a significant improvement in powder feed rate with a small amount of air

Aeration Hopper" eliminates powder clogging and improves conveying efficiency Contributes to reduction of raw material loss and equipment installation costs associated with production scale-up

日東金属工業株式会社

NITTO METAL INDUSTRY Co. (Head Office: Chuo-ku, Tokyo; President: Masaki Oyama), a manufacturer of industrial stainless steel tanks and agitation equipment, conducted experiments on pneumatic conveying of flour using its product "Aeration Hopper," which contributes to more efficient feeding of powder materials. Flour conveying efficiency was 2.87 times higher than without the product.

Powders are extremely difficult to handle because their behavior varies greatly depending on their properties and the environment in which they are handled. We receive many inquiries about the handling of powders on a daily basis, and among them, we receive many complaints about "not being able to supply sufficient amount of powder to the next process due to powder clogging.

We have a lineup of "aeration hoppers" that can solve such problems, and we conducted an experiment to demonstrate their effectiveness so that our customers can choose our products with confidence.

Aeration hopper main unit

An aeration hopper is an attachment attached to the outlet of a powder material tank.

By drawing in air, it fluidizes the powder inside and promotes its discharge.

As a result, the use of the aeration hopper has greatly improved conveying in two ways. 1.

1. flour conveying capacity has increased 2.87 times

(2) No flour left in the tank could be conveyed.

Experimental results (flour conveying efficiency)

Without aeration hopper, flour remained inside the hopper

With aeration hopper, all the flour was discharged

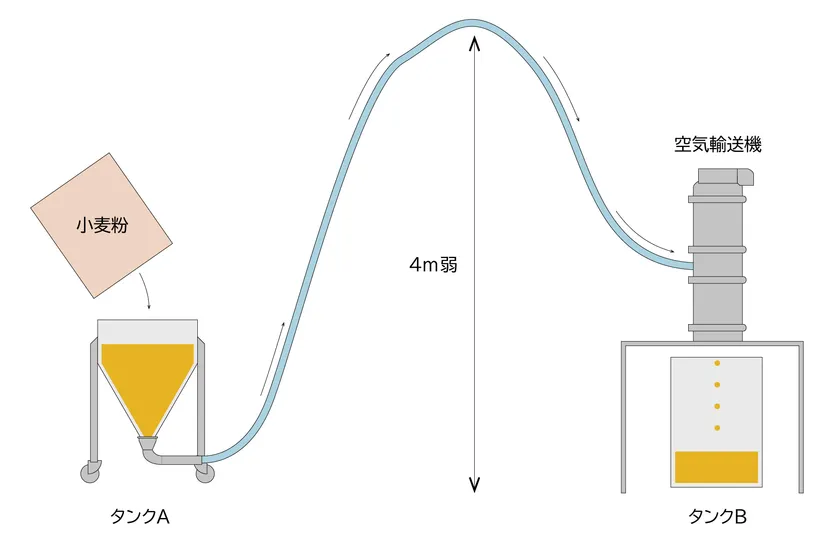

Experimental Method

Flour is conveyed from tank A (left image) to tank B (right image) using a pneumatic conveyor. An aeration hopper is installed in tank A, the source of the flour, and the amount of flour conveyed is weighed at tank B.

The amount of flour conveyed was compared with and without the aeration hopper.

Experimental layout

1. flour conveying capacity increased 2.87 times

By using the aeration hopper, the average conveying capacity (kg/h) of flour increased 2.87 times. Compared to normal, a larger amount of flour can be supplied to the next process in a shorter time.

In addition to reducing the time required for conveying, it also reduces the cost of installing new equipment, for example, purchasing a new pneumatic conveyor to increase the amount of flour conveyed when scaling up production, or installing a new air compressor (if the air supply is insufficient).

No air compressor

Conveying capacity (kg/h): 256

Supply pressure (MPa): 0.37

Aeration hopper pressure consumption (L/min): -0.37

With aeration hopper

Conveying capacity (kg/h): 735

Supply pressure (MPa): 0.37

Aeration hopper pressure consumption (L/min): -

Comparison value

Conveying capacity (kg/h): 2.87

Supply pressure (MPa) : -

Aeration hopper consumption pressure (L/min): -

*Transfer capacity is the average value of the results of multiple repetitions of powder transfer. 2.

2. no flour left in the tank could be conveyed

With the normal conveying method, flour formed a rathole in the hopper. A rathole is a phenomenon in which flour adheres to the hopper wall and remains in a doughnut shape when discharged. Since the entire amount of flour in the hopper cannot be discharged, this leads to material loss and quality inconsistency.

On the other hand, when an aeration hopper is used to fluidize the flour near the discharge port, adhesion to the wall surface is prevented and the entire amount is discharged without creating ratholes. Since no powder remains in the hopper for discharge and conveyance, material loss is reduced and a stable supply of raw materials to subsequent processes becomes possible.

What is an aeration hopper?

The aeration hopper is an attachment attached to the outlet of a hopper (conical) type tank that supplies powder materials. Air is supplied inside the hopper to fluidize the powder like a liquid and promote the discharge of the powder.

We are happy to provide a demonstration using actual powder materials for your consideration. Please feel free to contact us.

For more information on the structure, principle, and demonstration video of the aeration hopper, please click here.

https://www.nitto-kinzoku.jp/shop/g/gph-ar-tht/

Aeration hopper main body

Aeration hopper installation image

About NITTO METAL INDUSTRY Co.

NITTO METAL INDUSTRY is a manufacturer of industrial production equipment that contributes to the creation of new value and product manufacturing for customers through stainless steel containers and agitation equipment.

NITTO METAL INDUSTRY was started in June 1957 for the purpose of manufacturing stainless steel products and containers for household use. Today, NITTO METAL INDUSTRY designs, manufactures, and sells stainless steel containers and agitation equipment used in various fields such as cosmetics, food, chemicals, and semiconductors in Japan and abroad, with a focus on the pharmaceutical industry, at two locations in Japan.

With over 65 years of experience, we offer custom-made stainless steel vessels and agitators to our customers.

■Company Profile

Company name: NITTO METAL INDUSTRY Co.

Location: 2-358, Yashio, Saitama, Japan

Establishment : June 1957

Representative Director: Masaki Oyama

Business Description: Manufacture and sales of industrial stainless steel containers and agitators

URL : https://www.nitto-kinzoku.jp/shop/default.aspx

For inquiries from the general public, please contact

Sales Department, NITTO METAL INDUSTRY Co.

E-mail address : sales@nitto-kinzoku.co.jp

TEL : 048-996-4221

- Category:

- Technology & Development